Exploring New Frontiers in Plastics: Revolutionizing 3D Printing TechnologyIntroduction

Introduction:

In recent years, the world of manufacturing has witnessed remarkable advancements in 3D printing technology. While both plastic and metal 3D printing have their own unique advantages, it is plastics that have taken the lead in terms of revenue generation. This blog post dives into the realm of plastics and highlights the latest advancements, focusing on two exciting technologies: Polyether Ether Ketone (PEEK) 3D printing and Thermoplastic Polyurethane (TPU) 3D printing. Join us as we explore the innovative possibilities that these technologies offer.

1. Plastic 3D Printing: A Rising Star

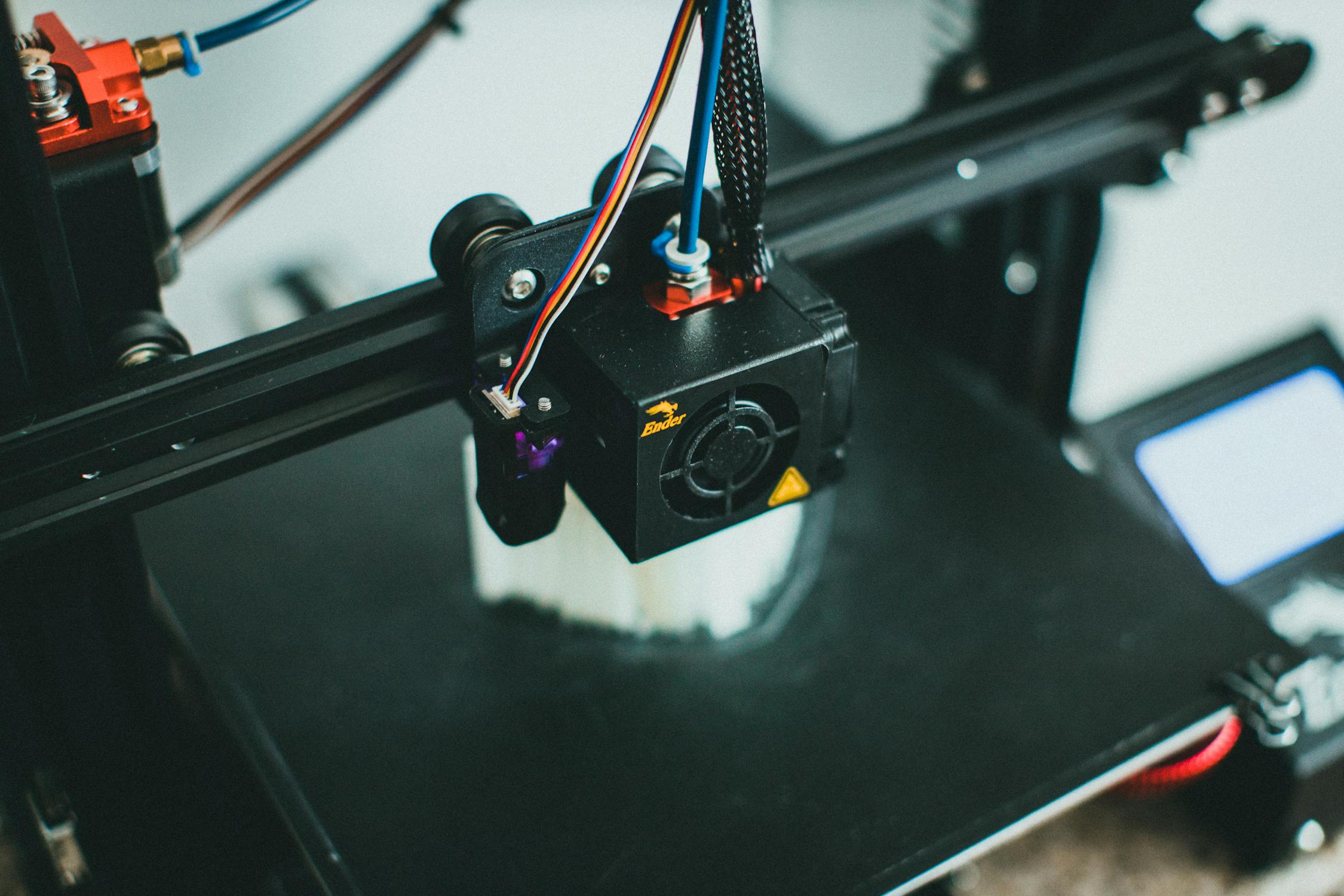

Plastic 3D printing has witnessed exponential growth, outpacing its metal counterpart in revenue generation. The preferred method for plastic 3D printing, according to a recent survey, is Fused Deposition Modeling (FDM), accounting for 56% of the market. Stereolithography (SLA) trails behind at 20%. This growth can be attributed to the wide range of applications and benefits that plastic 3D printing offers.

2. Unleashing the Potential of PEEK 3D Printing

Polyether Ether Ketone (PEEK) is a high-performance thermoplastic renowned for its exceptional mechanical, thermal, and chemical properties. PEEK 3D printing has revolutionized the manufacturing industry by enabling the production of complex parts with superior strength and durability. With its excellent resistance to heat, chemicals, and wear, PEEK is widely used in aerospace, medical, and automotive industries. The ability to 3D print PEEK parts opens up new avenues for cost-effective production and design flexibility.

3. Breaking Boundaries with TPU 3D Printing

Thermoplastic Polyurethane (TPU) is a versatile material known for its elasticity, durability, and resistance to abrasion. TPU 3D printing offers exciting possibilities in various industries, including footwear, sports equipment, and consumer goods. The ability to produce customized, flexible, and lightweight parts makes TPU an ideal choice for applications requiring comfort and impact resistance. By harnessing TPU 3D printing, manufacturers can bring innovation and personalized products to the market faster than ever before.

4. Expanding Applications: From Prototyping to Mass Production

Both metal and plastic 3D printing are instrumental across a wide range of applications. Prototyping, tooling, low-volume production, mass customization, and serial production are just a few areas where 3D printing is making significant strides. One noteworthy application is the use of metal 3D printing to create plastic parts by 3D printing the tooling for injection molding. This innovative approach offers cost savings, faster production cycles, and enhanced design possibilities.

Conclusion:

As the world of manufacturing continues to evolve, plastics have emerged as a frontrunner in the 3D printing revolution. Polyether Ether Ketone (PEEK) 3D printing and Thermoplastic Polyurethane (TPU) 3D printing are pushing the boundaries of what is possible, enabling manufacturers to create complex, customized, and high-performance parts. Embracing these new technologies opens doors to improved efficiency, reduced costs, and endless design possibilities. With plastics leading the charge, the future of 3D printing is brighter than ever.

No comments